The Challenge

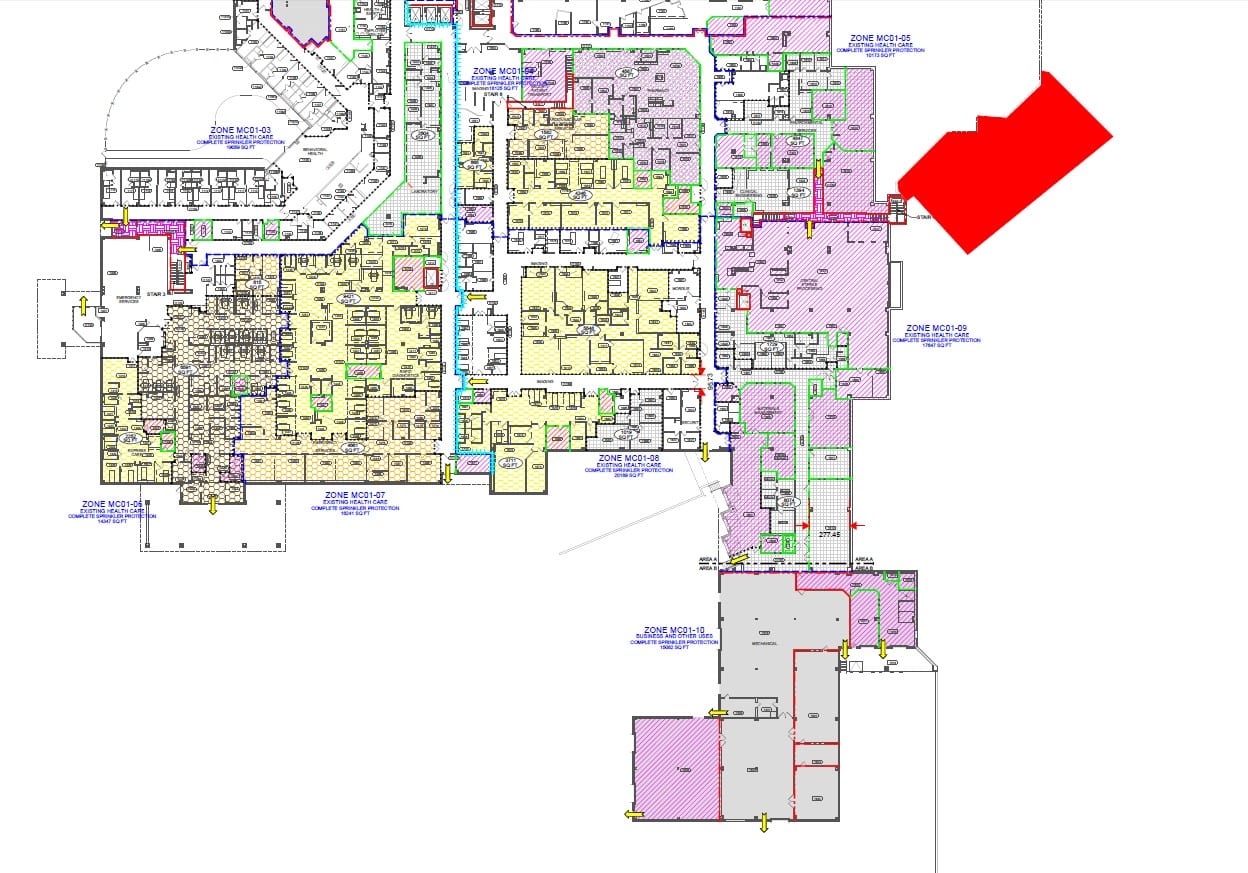

The Meritus Medical Center in Hagerstown, Maryland was in the process of constructing an expansion to their existing hospital facility, which included running new subgrade utility lines within 100 feet of the existing facility. Because the site’s soil conditions included bedrock, blasting was required to excavate the bedrock and dig trenches for new utility lines. Meritus was concerned that vibration levels generated by the blasting would impact sensitive medical equipment located within their facility, primarily magnetic resonance imaging (MRI) and computerize tomography (CT) machines.

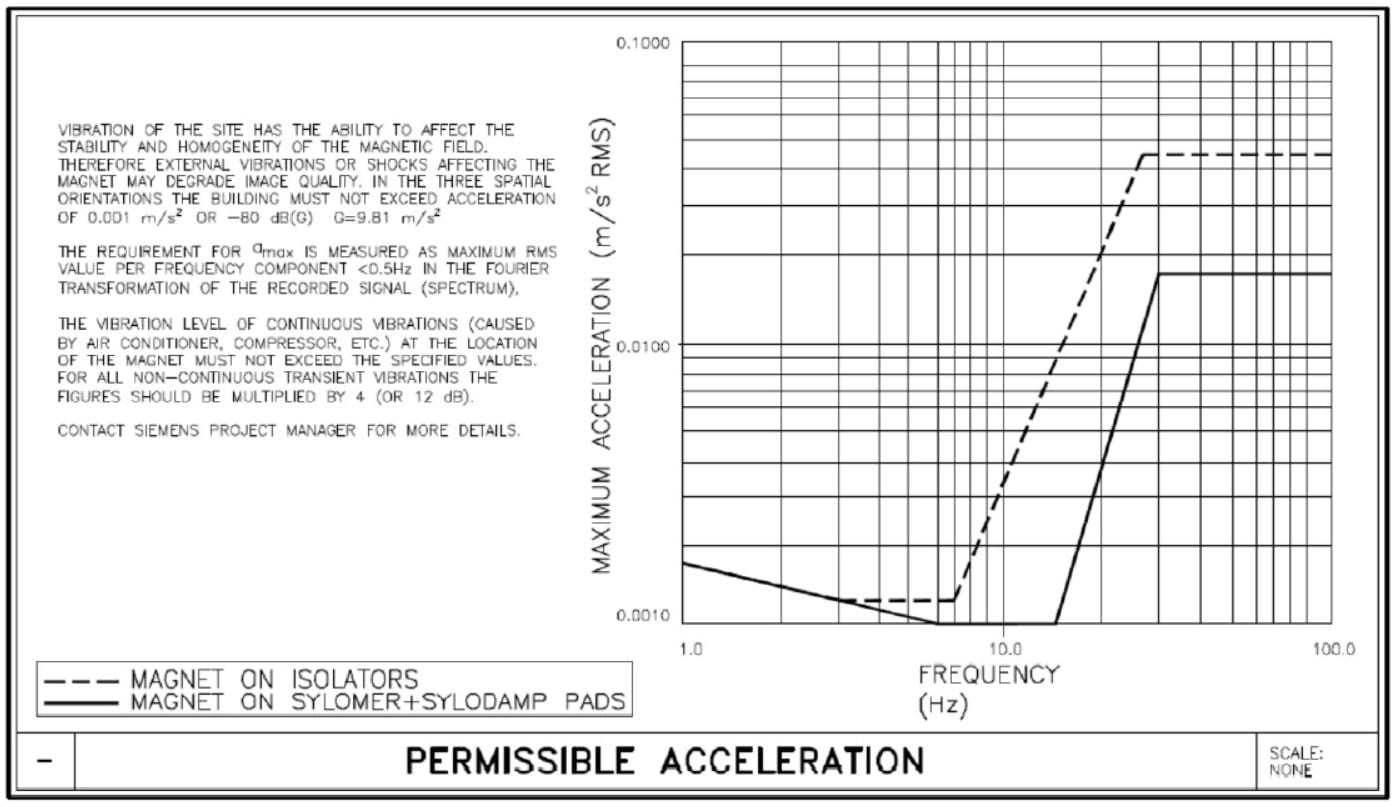

Meritus’ geotechnical engineer (Triad Engineering Inc.) recommended that vibration generated by the blasting be analyzed to determine the potential impact upon the sensitive equipment and that levels be monitored during the blasting. Triad and the blasting team are very familiar with vibration impact upon buildings and were not concerned about damage to the existing medical facility but were unsure of the impact upon the medical equipment. Vibration criteria for medical equipment such as MRI and CT machines is much lower than that used to determine building damage. Therefore, specialized vibration measuring instrumentation must be used to monitor vibration impact upon the sensitive medical equipment. Furthermore, vibration impact can cause disruption in the imagery generated by the equipment.

Our Solution

Phoenix Noise & Vibration coordinated with Meritus and the construction team to first determine the type and location of the sensitive medical equipment within the hospital. The vibration criteria for the various types of medical equipment was reviewed to establish which equipment was more likely to experience vibration impact based upon criteria level and proximity to the blasting. Phoenix Noise & Vibration also coordinated with the equipment manufacturer to verify the vibration specifications. This review determined that the MRI and CT machines were most sensitive.

Once it was determined that an MRI and CTs were the most sensitive equipment, Peak Particle Velocity (PPV) vibration levels were calculated by the blasting team using the charge load required to break the bedrock. The blasting team was able to provide calculated vibration levels in terms of PPV values for two types of charge, low and high. Phoenix Noise & Vibration then used the PPV values to calculate the expected vibration levels at the location of the sensitive MRI and CT equipment to determine if their vibration criteria would be exceeded.

Based upon the calculated vibration levels, it was determined that the criteria would be exceeded and that the most effective approach to mitigate vibration impact upon the sensitive equipment was to coordinate the blasting activity with a planned shutdown of the equipment, which would result in the equipment being offline for a thirty minute duration. This required the blasting team to complete all prep work prior to the equipment shutdown so that all blast charges could be detonated at one time, thereby minimizing hospital downtime.

The Results

Phoenix Noise & Vibration was on site the morning of the blasting activity to monitor vibration levels at the location of the hospital’s nearest MRI. The monitored vibration levels were used for comparison with the calculated vibration levels and to determine the level of impact upon the MRI. Due to proper planning of construction activity, the blasting was able to occur within a relatively small window of time, minimally disrupting hospital activity without impacting the hospital’s sensitive equipment.