The Challenge

AdvanceTEC was hired by the National Institute of Standards and Technology in Gaithersburg, Maryland to install a new Zeiss Xenos. The Zeiss Xenos is capable of providing measurement positioning accuracy below 100 nanometers, which means that if present, building vibrations above specified thresholds will impact the accuracy of the measurement device. This device required vibration levels to be below the VC-E curve. It is common for scientific equipment similar to the Zeiss Xenos (e.g. MRI and CT machines, sensitive microscopes, etc.) to have vibration level specifications for the building in which they are being installed.

Due to the vibration specification requirements of the new measuring tool, Phoenix Noise & Vibration was contracted to help determine if the laboratory where the tool was going to be located met the tool’s requirements and that any modifications made to the laboratory during the tool’s installation did not change the vibration conditions of the laboratory.

Our Solution

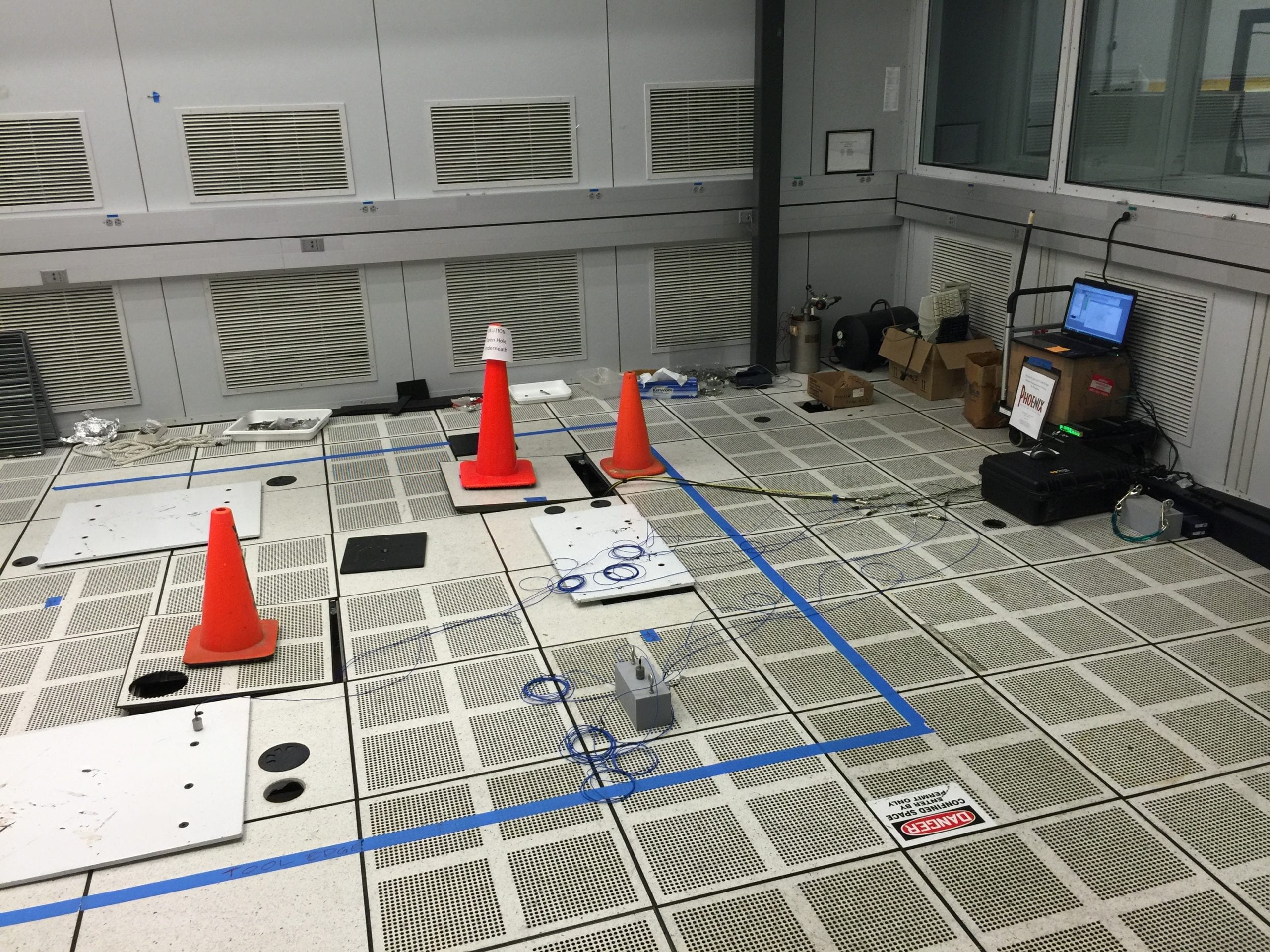

The first task was to determine if the laboratory’s current construction conditions met the vibration specification requirements for the Zeiss Xenos measuring tool. If the requirements did not meet the requirements, then modifications to the laboratory would be required. After discussions with AdvanceTEC representatives, it was decided that Phoenix Noise & Vibration would visit the laboratory to conduct a 24-hour vibration measurement survey to facilitate monitoring of typical building conditions throughout the day and night.

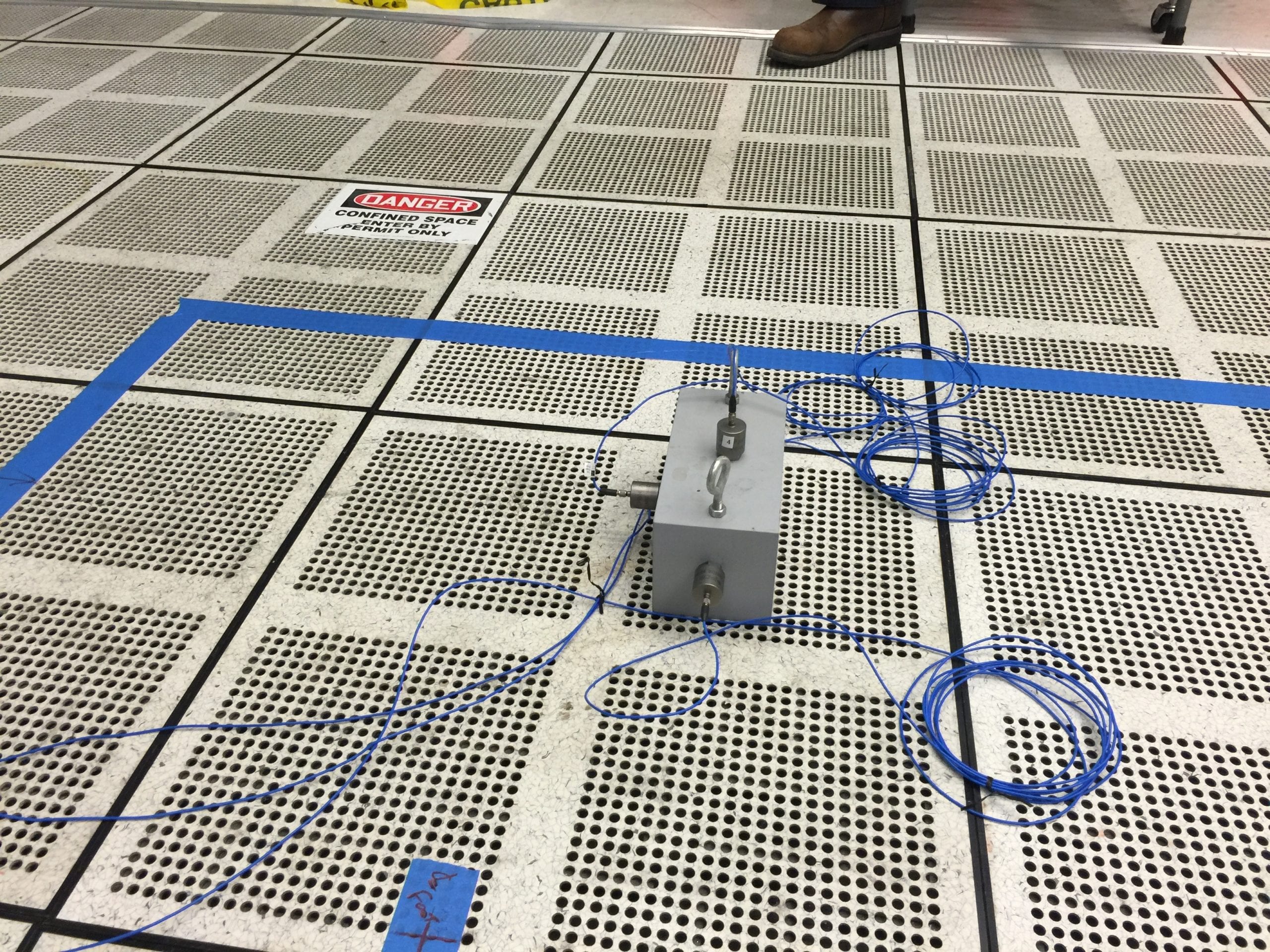

Since the laboratory was previously used for other sensitive measurement equipment, it already had a pneumatically isolated concrete slab in place. For the vibration measurements, the compressed air in the pneumatic isolators was released, allowing the isolated slab to sit on the structural slab of the building. This was because AdvanceTEC was interested in determining if the isolation slab was necessary for the Zeiss Xenos measuring tool. Measurements were made at three locations within the laboratory; the building’s structural slab, the deactivated isolated concrete slab, and on a pedestal on top of the isolated concrete slab that would be used to support the new measuring tool. At each measurement location, triaxial (x, y, and z-axis) measurements were made.

Based upon these pre-installation vibration measurements, the existing vibration levels within the building were below the most sensitive criteria in each axis direction for the Zeiss Xenos measuring tool. This allowed AdvanceTEC to move forward with installation of the device without modifications to the structural supports.

After installation of the new measuring tool, Phoenix Noise & Vibration returned to the site to conduct another 24-hour vibration measurement survey within the laboratory to determine if the vibration conditions may have changed due to the changes brought about by the construction. The follow up survey determined that the vibration conditions had not changed and that the Zeiss Xenos measuring tool should be able to operate within its required tolerances without interruption due to vibration.

The Results

Phoenix Noise & Vibration was able to work with AdvanceTEC and NIST to determine if the building conditions in which they had planned to install the new measurement tool met the specifications required for that tool to function as designed. Without proper planning, it is possible that the tool is installed into a building environment which is not suitable for its operation. Alternatively, the specification of unnecessary isolation could have occurred, as it was found that the pneumatically isolated concrete slab was not required in this application. While vibration measurements may seem like an additional step in completing a project, the information provided by the measurements is invaluable relative to the potential costs associated with overbuilding or installation errors.